Bio-energy with carbon capture

Advantages of Capsol's point source capture technologies

Additional district heating generation

For customers that are connected to a district heating network, the CapsolEoP® solution can boost their energy production during winter months. Here our technology makes a capture facility an additional revenue generator.

Engineering work for clients has produced energy consumption numbers of 0.5-1.5 GJ/tonnes of CO₂ captured, depending on the composition and temperature of the flue gas (not including liquefaction).

Low energy consumption and fully electric

A Capsol carbon capture plant can be solely powered by electricity, which results in an overall low energy consumption due to the highly efficient internal heat pump effect for the conversion from electricity to heat.

Stand-alone unit simplifies integration

Our technologies are designed as stand-alone units that limits modification needs of customer’s facilities and minimize downtime of the customer’s plant during the construction period. Simpler integration reduces capex and project risk.

Safe and cost-effective handling of solvent

Our proven and safe HPC (hot potassium carbonate) solvent is relatively cheap and available globally. This is different to Amines, where emitters may be locked in with one expensive solvent supplier. In addition, HPC offers superior HSE (health, safety and environment) and easier permitting.

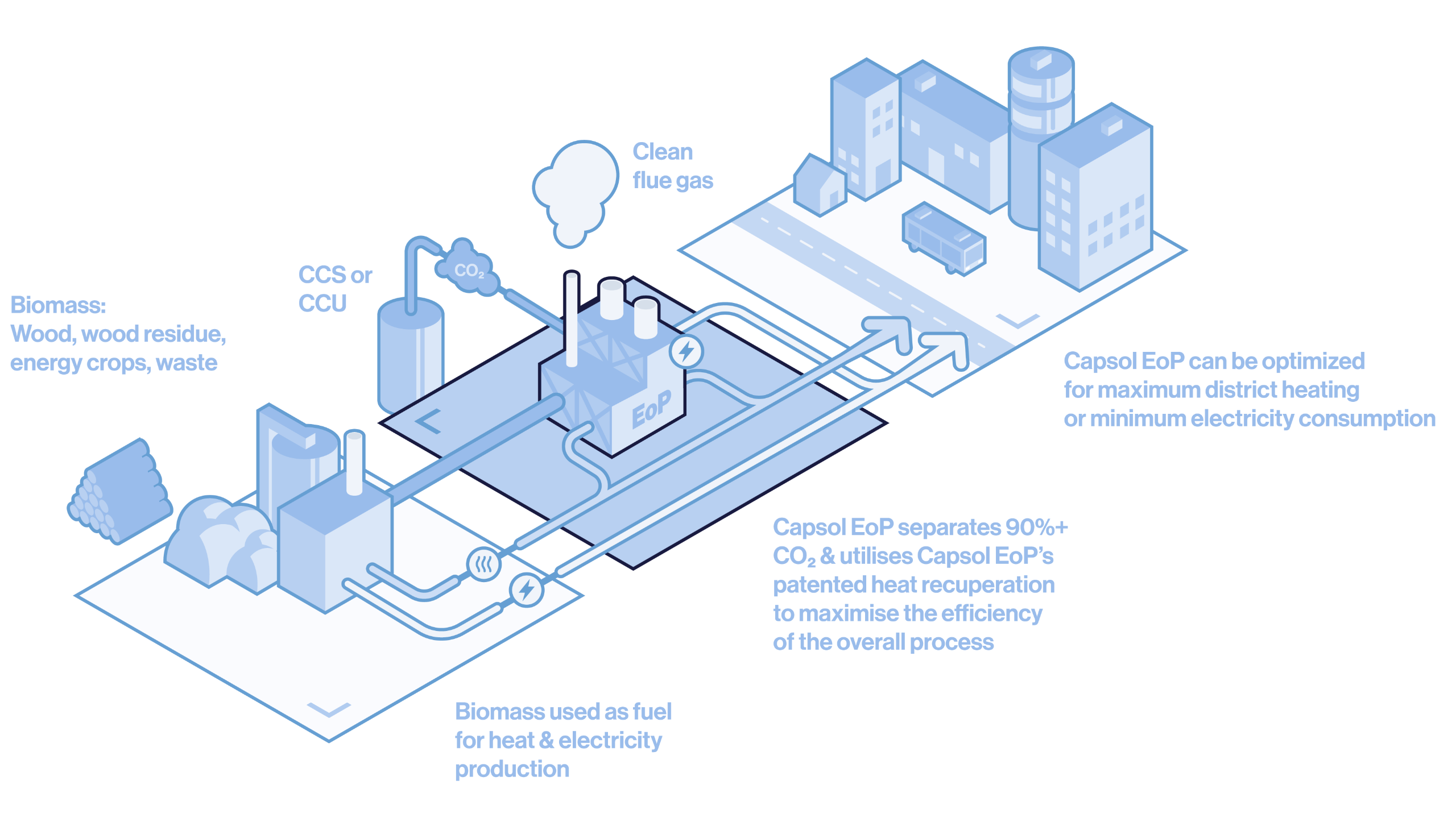

High-level overview of Capsol's bio-energy capture solution

Stockholm Exergi - Europe's largest BECCS project

The biomass-powered combined heat and power (CHP) plant Värtaverket in Stockholm, Sweden, was Capsol’s first license agreement for CapsolEoP®.

In addition to being awarded EUR 180 million by EU, Stockholm Exergi has signed permanent carbon removal agreements with Microsoft and the Frontier fund.

On March 27, 2025, Stockholm Exergi made final investment decision (FID), moving the project into the construction phase. The facility is scheduled to begin operations in 2028.

With a full-scale deployment of 800,000 tonnes of CO₂ per year, Värtaverket will be Europe’s first large-scale negative emissions plant when operational.

We care. We can. We capture.

Find out how Capsol can help you capture CO₂ and significantly reduce associated capture costs.